Copy link to clipboard

Copied

Hello,

I'm trying to design a label for a conical shaped container. Somewhat succeeded by using the envelop tool.

But the results are not that satisfactory. Unable to attach .ai for reference - Use G Drive link. Kindly help

1 Correct answer

1 Correct answer

Vishnu,

As far as I can make out, to get it right you can start out with a rectangular label (the full label) with about W = 24.27 cm and H = 4.69 cm. Hopefully you already have that.

And I believe you can get the right (un)distortion if you:

1) Scale the full original label by 88.6% (leave the height unchanged) corresponding to W = 21.5 cm (with the measures above),

2) Apply Effect>Warp>Arc with a Bend of 27.778%.

Explore related tutorials & articles

Copy link to clipboard

Copied

Thank you very much for your reply. Last question regarding the keyline. So the final file for production will only be the adjusted artwork without showing the bleed or template outline because it's masked, right? Btw, the client cancel this project, but I'm asking just for the knowledge sake

Copy link to clipboard

Copied

I will explain the work flow for you and the entire community users.

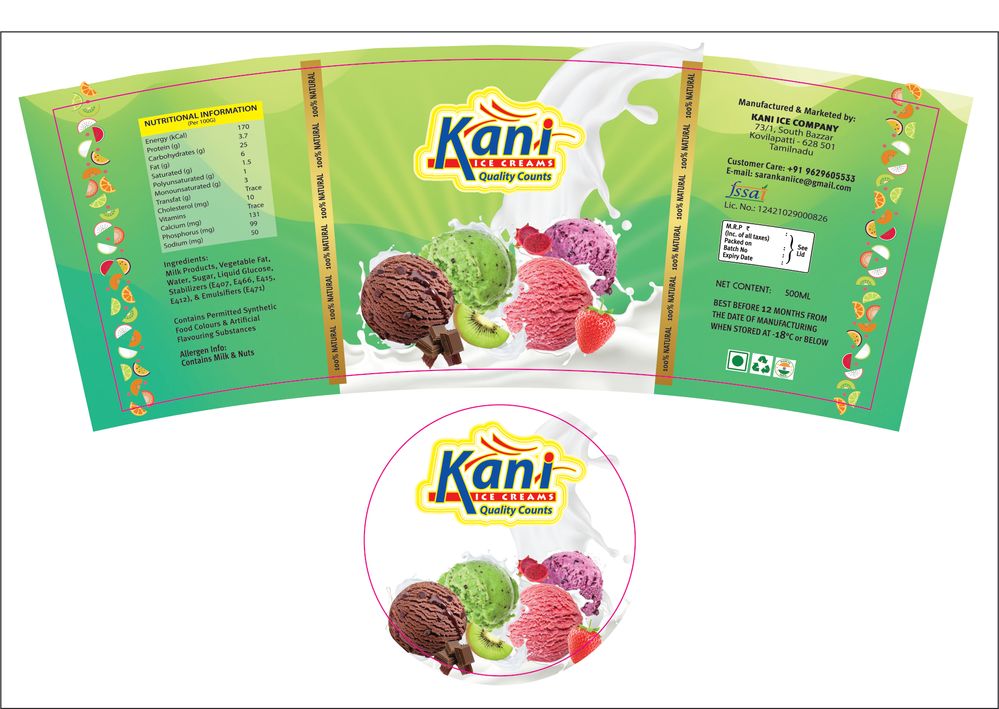

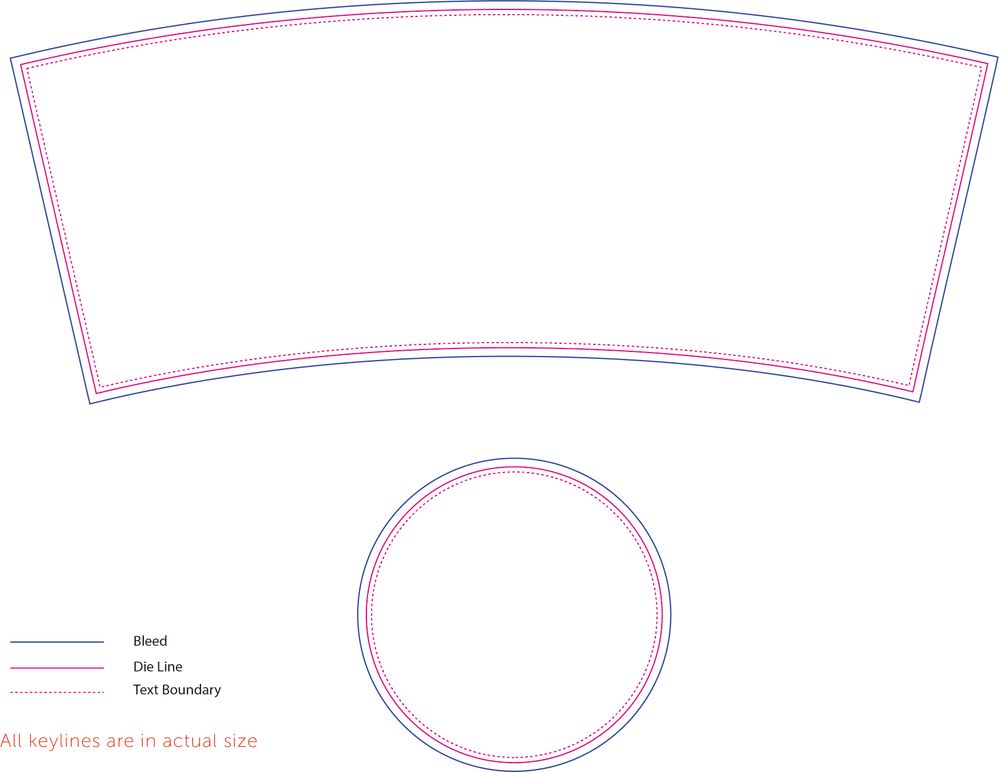

We assume that a manufacturing / packing company is about to launch a new product. This product requires an attractive packaging. The company finds a designer and a printer to achieve this. The printer will ask for a physical sample of the product or a 3D design file. Then he will export a UV Texture from the design or he will create a 3D design himself to work with. This UV Texture is then converted to a Keyline and will be sent to the designer. Second image is an example.

Now the designer will create an artwork and adjust it with keyline. In the example keyline, the blue line is maximum boundary for the artwork. The pink line is the cutting line ( Die cutting / Laser cutting). Dotted pink line is the text boundary (The important stuff including the logo, text and legal information should not exceed the dotted line). Space between the blue line and dotted line is the "margin of error" for the printer. If the important stuff exceeds the dotted line, it might be cropped out. When the designer sends the artwork to the printer, he will mask the entire curved artwork upto the blue line and will put the die line on top of the artwork. First image is an example (It is a 500ml conical shaped plastic container for ice cream, IML - In Mould Labeling is the process).

Printer will print the entire artwork up to the bluline and at the time of cutting he will follow the die line. Normally the artwork is printed on to a white substrate (Base material / plastic film). Depending on the accuracy of the cutting machine the die line will slightly vary, thats why we give him enough space to play with. If the artwork is not exceeded upto the blue line, and the cutting line varies, the white substrate will be visible on final output.

See the linked video to see the final output after IML moulding ( Process - Injection moulding with robotic IML)

Final product video link (Gdrive)

Copy link to clipboard

Copied

Thank you for your great explanation. So, in the final file sent to the printer, do I need to include the die line or should I hide it? In your first image, the pink die line is still visible.

Copy link to clipboard

Copied

Die line should be visible. So the printer can cross check it with his original key line to make sure there are no mistakes.

Copy link to clipboard

Copied

Icehall, and Vishnu,

I have been hindered since 24th September, and only just able to start catching up among other urgent matters.

This long outstanding question is the first one I have started on; I saw it in my Notification feed.

The following is in addition to the excellent explanation by Vishnu (I was unable to view the linked video).

I also believe that Vishnu can give you better help than I with some of the interpretation and guessing (as in step 3).

As mentioned earlier,

"Any adaptation of plane (or plain) artwork to conical surfaces is inherently an approximation with with inbuilt choices/inaccuracies/limits to usability.

Obviously, the usability of a simple adaptation depends on the nature and structure of the artwork, including the proportions and especially the width/height along the generating lines, where (further) customization may be needed."

This also applies to the Warp>Arc (or (Argh) way as mentioned, and besides there are countless ways of expressing the task, so this also applies to the present case "Your information is completely different to what I have ever seen in hitherto conical label cases".

There are a few things I find strange in the template:

The cutting line seems to have three rounded corners and one sharp (top right). I assume it is meant to be rounded as well.

The dotted line is 10 mm inside the cutting line at the top and 5mm inside at the bottom; to the right it seems to be (coinciding with the full line) 5 mm inside all the way from top to bottom, but it extends past the cutting line to the left. I assume it is meant to be 5 mm inside the cutting line in both sides. As a comment, when warping by the same (bending) angle, it is impossible to have the same distance inside from top to bottom, instead it will be more at the top and less at the bottom (how much depends on the angle), which will also make it look right. This raises the question whether the 5 mm inside is supposed to be the minimum or the average, I assume it is insignificant in this case.

No bleed/maximum artwork boundary seems to be present. I assume you will just have to add a bleed to have the artwork extend enough past the cutting line, based on information from the vendor or by a safe guess.

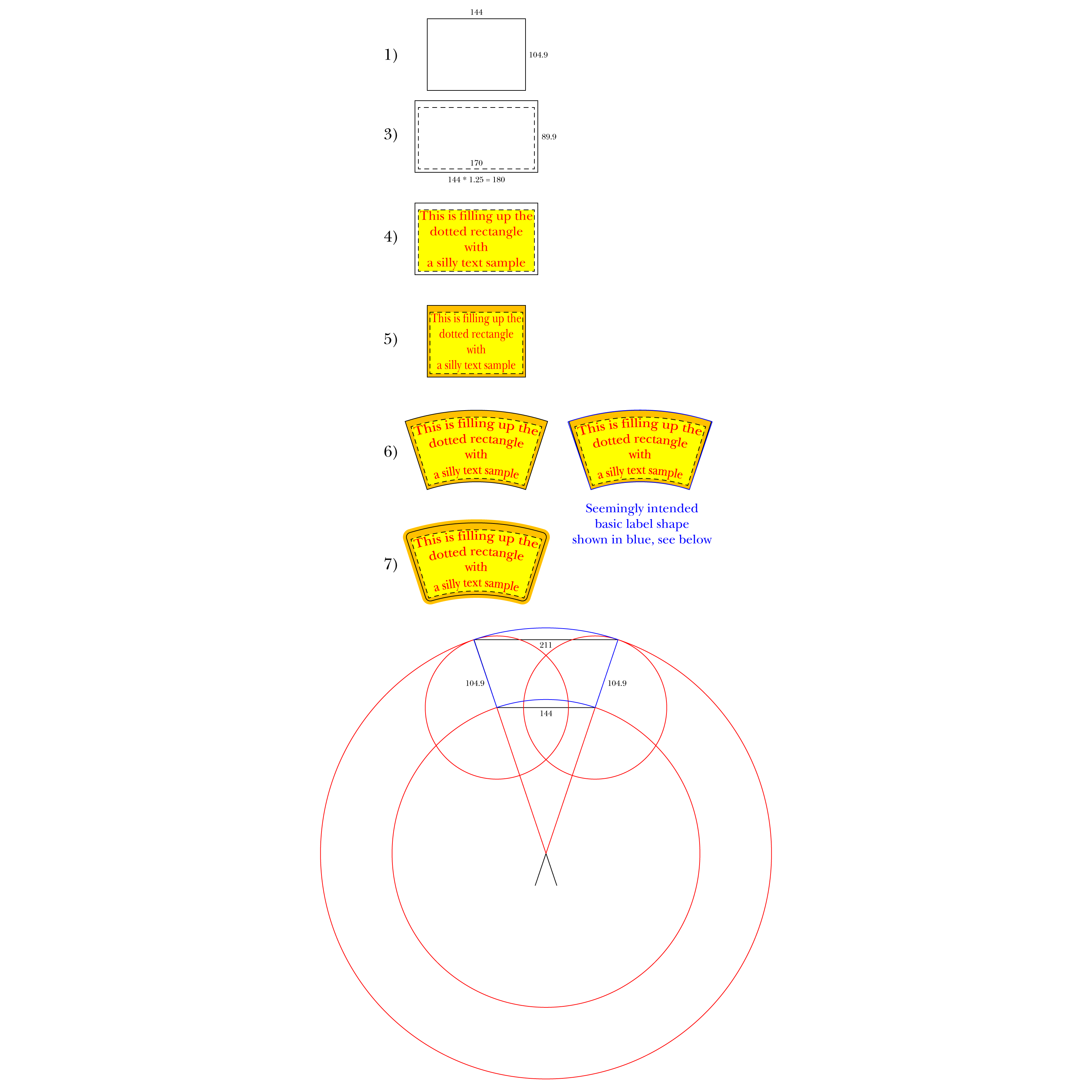

With the assumptions, you can try the following and see whether it looks right, see drawings below:

1) Create a (full) stroke/nofill rectangle corresponding to the cutting line with W = 144 mm and H = 104.9 mm, you can adjust the corners later;

To get the overall right proportions at the centre of the label (wider at the top and narrower at the bottom), rather than right at the bottom and (too much) wider towards the top, and corresponding to the actual (bent) length:

2) In the W box in Transform panel, increase the width of the rectangle to 180 mm (144 * 1.25);

To get the dotted rectangle inside the full line rectangle for text and other crucial artwork with the size W = 170 mm and H = 89.9 mm;:

3a) Object>Path>Offset Path>Set the Offset to -5 mm, then

3b) Deselect, then with the Direct Selection Tool click the top side of the new rectangle and Obects/Transform>Move it down by -5 mm;

3c) Click Dashed Line in the Stroke panel;

4) Create the crucial artwork including text to best fit within the widened dotted rectangle from 3);

This is meant to look right as a basic rectangular version of the label, as you would want it on a cylindrical container; and then:

5) Select everything and bring the width back to 144 mm, then add non crucial artwork behind everything to fill the full stroke rectangle from 1);

Now you have a funny looking label with compressed (crucial) artwork and non crucial artwork contained within the rectangle that is going to form the cutting line;

Now it is time for the warping:

6) Group everything from 5), then apply Effect>Warp>Arc with a Bend of 20%;

This ought to fit (close enough) the label from the vendor which you can place on top as a stroked path, see basic shape shown to the right based on the vendor label drawing at the bottom.

Then you can:

7):

7a) Either hide the cutting line from 6), or hide the label from the vendor and round the corners of the cutting line from 6) and use that.

7b) Add the bleed with non crucial artwork behind everything.

Click/RightClick to see in new Tab, and Click again to get closer

Copy link to clipboard

Copied

Hello Jacob,

The Gdrive link works fine, even though I have added new video link for you.

Download the video to wathch it.

It is wetransfer link

Copy link to clipboard

Copied

Thank you Vishnu, now the Gdrive link (also) works for me.

Exquisite work on the Kani icecream.

Copy link to clipboard

Copied

Thankyou Jacob,

Im working for a company which provides premium packaging solutions for FMCG sector in India & UAE. Major clients are in to Ice Cream and other ready to eat products. Unfortunately I cannot share the premium works of our major clients due to copyright protection. Kani icecream is one tiny exception. We use Adobe suit of applications to deliver the exclusive packaging requirements of the FMCG sector. Adobe support community and Youtube content creators helped me a lot to get here. So Im more than happy to give back to the community. You can divert / tag all community posts that requires real world applications ( Including but not limited to Illustrator, Photoshop, any 3D applications, 3D Printing, CNC Machining apps, IML & Injection Moulding).

Thankyou for your contributions to the community.

-

- 1

- 2

Get ready! An upgraded Adobe Community experience is coming in January.

Learn more