- Home

- Photoshop ecosystem

- Discussions

- Create a pattern in place of gradient? Halftone cl...

- Create a pattern in place of gradient? Halftone cl...

Create a pattern in place of gradient? Halftone clipping

Copy link to clipboard

Copied

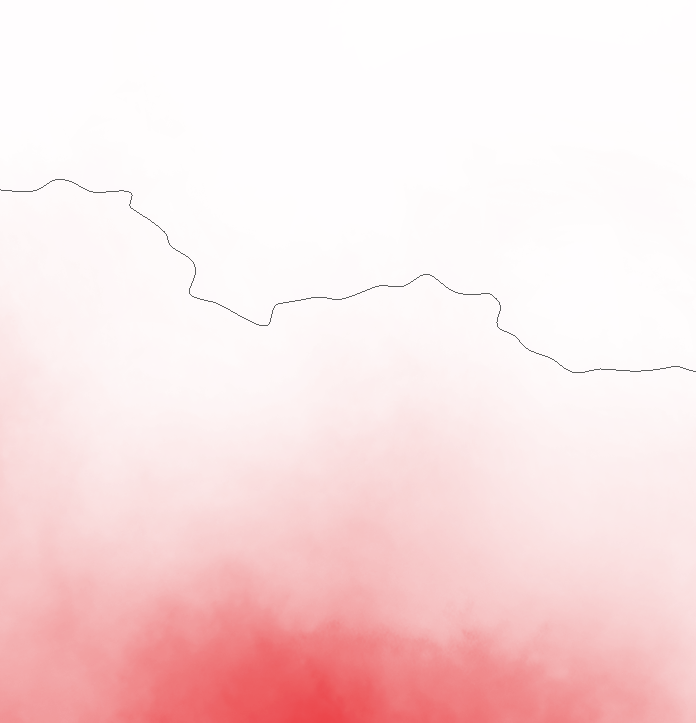

I'm running into an issue where this halftone spot color is clipping at approx 1-2% on press. The path shown represents this approx area. Rather than clip and have that show up as a hard break, I need to soften it. I can't feather it as it just moves the area being clipped to another location. Wondering if there is a way to create a softening effect without changing the % of color. An example that came to mind that I don't know how to put into practice is essentially creating a random-ish pattern at a low % that isn't clipping that gives the effect of soft edges. Ideas?

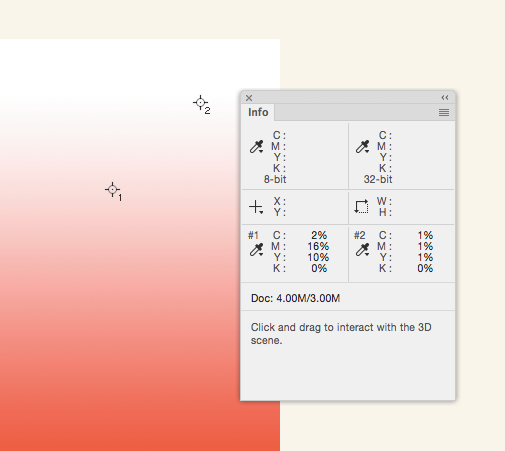

This is a screenshot of the sample - think smoke. The red is printing white ink.

Thanks

Explore related tutorials & articles

Copy link to clipboard

Copied

I'm running into an issue where this halftone spot color is clipping at approx 1-2% on press.

So you may want to keep a 1% tone throughout the whole image.

You could also Add Noise – ideally in a separate layered File so you can add the noise on a 50% grey Layer and use Blend Modes and if necessary Blend Modes.

Copy link to clipboard

Copied

File is running in three layers. A top layer we'll call "Smoke" - white ink. A middle layer with noise in 4CP. And a bottom layer in white ink that is 1% with full coverage (like 3 plates). Press is clipping the 1 to 2 % white in both layers. Not presently concerned with losing the bottom layer.

File (Pshop images linked into Illustrator) does have transparency reducing the original percentages. So a 1% in original is a fraction in print file. This is certainly causing the clipping but has to be this way to produce the desired effect in other areas. Wanting now to smooth the transition of what is and isn't printed. Right now a hard break. Won't be able to smooth with transition halftones. Won't be able to introduce a full coverage "1%" as that changes the total look. Want to transition with what I can only think of as a fixed dot blend - where the percentage doesn't change but the distance between dots does giving the effect of a blend.

Copy link to clipboard

Copied

A top layer we'll call "Smoke" - white ink. A middle layer with noise in 4CP. And a bottom layer in white ink that is 1% with full coverage (like 3 plates).

That seems confusing, Layers are not Spot Colors and Spot Colors are not Layers so what are you actually printing?

File (Pshop images linked into Illustrator) does have transparency reducing the original percentages. So a 1% in original is a fraction in print file. This is certainly causing the clipping but has to be this way to produce the desired effect in other areas.

If the print process has the first printing dot at 2% then it is irrelevant how your layout combines elements, 1% will just not print.

Which print process is it?

Copy link to clipboard

Copied

This is a digital press with capability at press to print 3 layers in 1 pass. 4cp+1. I'm sending 3 files to press - top, middle, bottom. The top layer I've screen shot in OP.

You're right, 1% is just not printing. I need to introduce a blend that does print to smooth out the transition from non printing to printing.

Copy link to clipboard

Copied

You're right, 1% is just not printing. I need to introduce a blend that does print to smooth out the transition from non printing to printing.

Then I suspect that in classical print (offset, gravure, …) you would need to do the halftone separation manually and print a bitmap that you assign the spot color to.

But the digital print is probably some sort of ink-yet?

Copy link to clipboard

Copied

This is a digital press with capability at press to print 3 layers in 1 pass. 4cp+1.

Your "layer" description makes it sound like you are really not making a spot color separation. If the press is capable of printing CMYK + a spot color, and you want to spec the extra plate, you have to set the spot color plate up as a Spot Channel in a CMYK mode file, or assemble the page in InDesign where the spot color could be placed as a Monotone and a 5-color PDF can be exported.

If you send the file as a typical layered RGB or CMYK file with no extra channel, the color would get separated to the CMYK plates and the break would be exaggerated—there would be clipping of 1% dots on 3 plates (CMY) rather than the single spot color plate.

There's no way to overcome the mechanical capability of the press—if it can't print a 1% dot nothing you do to the file will change that.

Copy link to clipboard

Copied

Your "layer" description makes it sound like you are really not making a spot color separation. If the press is capable of printing CMYK + a spot color, and you want to spec the extra plate, you have to set the spot color plate up as a Spot Channel in a CMYK mode file, or assemble the page in InDesign where the spot color could be placed as a Monotone and a 5-color PDF can be exported.

I'm not having trouble getting the spot to print just a percentage reproducing within the print. My layering mention is complicating things but not associated with the desired outcome. The monotone photoshop file setup as a spot channel is linked within Illustrator and exported as a PDF. There is no color in the process channels. I would say you're accurate - not really making a color separation.

There's no way to overcome the mechanical capability of the press—if it can't print a 1% dot nothing you do to the file will change that.

Accurate. But, if I can print a 2% dot, I can in the file, create a blending with that 2% that looks like it reproduces 1%. I just don't know how to go about doing that seamlessly along the length of the path.

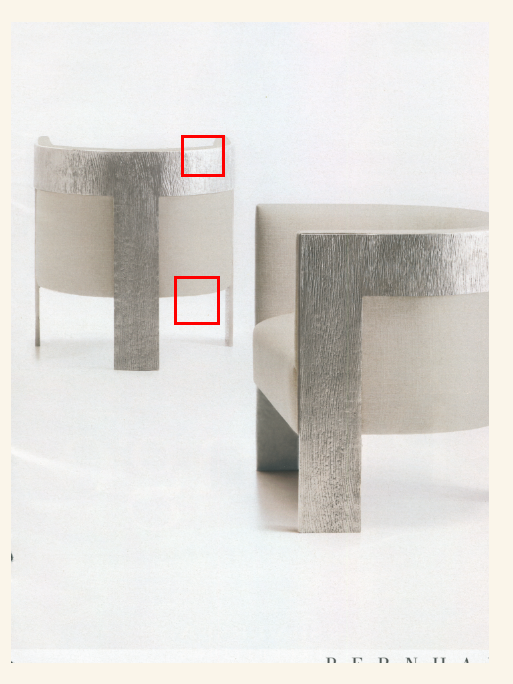

Rough example

Copy link to clipboard

Copied

But, if I can print a 2% dot, I can in the file, create a blending with that 2% that looks like it reproduces 1%. I just don't know how to go about doing that seamlessly along the length of the path.

Changing the pixel percentages won't change the mechanics of the halftone screen—halftone gray levels are achieved by changing the dot size not the space between the dots. Stochastic screening uses same sized spaced dots spaced (as in inkjet), and you could bypass the output device's halftone screening and make the 5th plate a dithered 1-bit bitmap, but that would very likely make things worse, because if the press can't hold a 1-2% halftone it will not reliably hold a dithered screen.

Copy link to clipboard

Copied

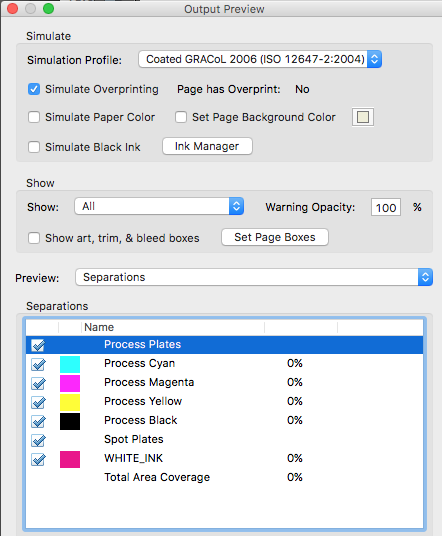

So the red has at least Magenta and Yellow, possibly even a bit of Cyan or Black?

If so you have set yourself a difficult task …

Edit:

The monotone photoshop file setup as a spot channel is linked within Illustrator and exported as a PDF. There is no color in the process channels. I would say you're accurate - not really making a color separation.

But the screenshot of Acrobat’s Output Preview window does not show a red spot color, just CMYK + White, so I am again confused about what’s actually going on.

How exactly does the digital press separate – a halftone screen pattern or a »dither«?

Copy link to clipboard

Copied

So the red has at least Magenta and Yellow, possibly even a bit of Cyan or Black?

If so you have set yourself a difficult task …

The WHITE_INK spot color separates to a 5th plate, which will print white ink and not the spot's magenta definition. I think it's common for printers to request the magenta definition so it's easier to see the plate in the PDF, but for true spot color printing the color definition doesn't change the separate plate output.

Copy link to clipboard

Copied

The WHITE_INK spot color separates to a 5th plate, which will print white ink and not the spot's magenta definition.

I understood that the magenta was just a stand-in color as the spot color is named »WHITE_INK«.

So on what does the white print?

When you talk about plates for digital printing you seem to be using conflicting terminology.

Please show the whole image and let us know the size to allow estimating how much of it is affected.

And once again: How exactly does the digital press separate – a halftone screen pattern or a »dither«?

Quite frankly I doubt that the straws you are grasping at will provide a viable solution.

Copy link to clipboard

Copied

When you talk about plates for digital printing you seem to be using conflicting terminology.

I've been assuming it's something like this:

White Ink Printing - Digital & Short Run Print | File Set-up and Design Ideas

I've also been assuming a halftone screen because it doesn't seem like you would have noticeable clipping between 0 and 2% with a stochastic screen.

Copy link to clipboard

Copied

Seem like valid assumptions.

But if one is to manually create the halftone pattern as a 1-bit image one would still need to know the the width/max.radius and angle (though that one will probably be 45˚ anyway).

Copy link to clipboard

Copied

We're going down a path that doesn't need to be explored. All I need is to create a noise type pattern to randomly break up the mechanical clipping happening at press to simulate dot percentages being lost and gradually blend the hard break. That just came to me, might help clarify the direction.

Copy link to clipboard

Copied

All I need is to create a noise type pattern to randomly break up the mechanical clipping happening at press to simulate dot percentages being lost and gradually blend the hard break.

You could try, but I doubt it will work because it doesn't change the halftone's variable sized dots.

The problem you are describing is actually common with any printing that uses halftones. Typically when you are running a gradation to paper you would check with the printer and find the smallest dot they can hold and run that percentage as your white point. 0% CMYK would be reserved for spectral highlights (think jewelry).

So something like below where you would let the smallest printable dot cover what would be clear. A 2% white ink halftone dot on clear substrate would not be visible to the naked eye. You would want to confirm that the minimum printable dot is in fact 2%.

Copy link to clipboard

Copied

You can see the minimum white point concept at work in most highend printing. Here the temptation may have been to let the background gradations go to 0%, but the printer set a white point percentage for the background and only let the reflection sparkles go to 0%.

Copy link to clipboard

Copied

But if one is to manually create the halftone pattern as a 1-bit image one would still need to know the the width/max.radius and angle (though that one will probably be 45˚ anyway).

Right I don't think the OP should try that, but it would be the only way to bypass the variable size dot screening at output. A 1-bit dithered bitmap would have no screen applied —there would be no screen angle

Copy link to clipboard

Copied

I assume you are printing on to colored paper? What color is it? Can you share the PDF?

Copy link to clipboard

Copied

Ha. Clear.

Copy link to clipboard

Copied

You're right, 1% is just not printing. I need to introduce a blend that does print to smooth out the transition from non printing to printing.

In case you are not aware, Photoshop's 8-bit CMYK Info rounds the output percentages. The output is 8-bit 256 levels of gray so to see output percentages that are not rounded set the Info to 32 bit and multiply by 100.

The more accurate output of my #2 sample (assuming to output device is capable of 256 levels of gray) is .4%c, .8%m, .4%y, 0%k. But this doesn't change the fact that the printer isn't capable of holding the 1% dots. I have assumed that you are printing to a separate plate offset press. Is that the case?

Copy link to clipboard

Copied

Digital. Press is capable of 4cp+Spot. File is monotone

Copy link to clipboard

Copied

Agree with excellent suggestion from c.pfaffenbichle on the 1% tone.

Depending on your printing process, you could introduce UCA. Under color addition to compensate for the dot loss.

More info here: The Hidden Power of Photoshop CS: Chapter 2: Color Separations. Pt. 2. By Sybex | 6 | WebReference

HTH

Copy link to clipboard

Copied

Wait a sec. – if it’s the white that prints the issue marked in the original screenshot would not be the 1% but the 99%, wouldn’t it?

Copy link to clipboard

Copied

There's been some developments in the file. What was initially unknown (thanks to project managers) was that the final output was much much larger than the sample I was producing (thought at time to be full size). The clipping was a result of trying to fit, for example 20", of a reducing halftone within an area of about .25" - which met the mechanical limits of the press. At full size, the clipping issue is disappearing. So remember that when communicating to your printers - scale is absolutely critical. Thanks for the resources, I think this is resolved for the moment.

T

Find more inspiration, events, and resources on the new Adobe Community

Explore Now