Copy link to clipboard

Copied

Dear all,

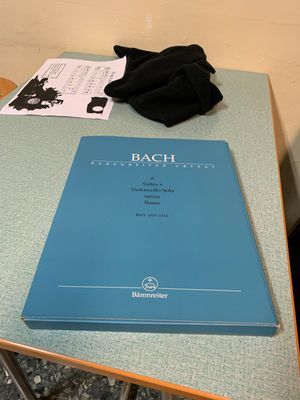

in my sheet music publishing journey I have now come to a point where I need to create a slipcase to house printed orchestral parts or editions made up of multiple elements (score + at least 5 parts). Here's an example of what I am trying to obtain:

An example of a cover from one of my recent editions is attached below (Piatti-Niobe-op22-Cover_v2.pdf).

The printer sent me a PDF of a model they use for creating a slipcase (also attached below). Looking at that model, though, I am having a hard trying to understand how it is supposed to be folded, since it looks upside down to me, as if the design had to go on the opposite side of the PDF.

So, here are my questions, hoping that someone with experience in this sort of things could help me learn how to do this:

- is this PDF model good and how would I go about creating a design for it? Is it possible in InDesign or should I use Illustrator? I am not too comfortable with Photoshop but could learn of course.

- is there any other model/template available (free or paid) for this kind of objects?

Concerning size: my editions have a page size of 232 x 305mm. How would I then go on calculating the proper dimensions for this slipcase? I am aware of some tools for the depth of the slipcase itself, as if I had to calculate the width of a book spine, but in my experience this is often too small—score and parts are saddle-stiched and after they get opened once, they tend to occupy more space than before.

Thank you so much to everyone who will be able and willing to help me learn this new, fascinating side of my activity.

1 Correct answer

1 Correct answer

"Do you suggest getting started in Illustrator and then moving to InDesign?"

I personally, based on your design I would do the entire project in Illustrator, but you can use both without issue. The dieline is much easier to create in llustrator. Since you already have your design in ID, leave it there. You will have to resize your ID document though as you need to make it as large as necesssary to accommodate all the panels and flaps in the dieline.

"When you say that you prefer to keep the pane

...Copy link to clipboard

Copied

Update:

Isn't the Direct Selection tool your best friend? 🙂 — a pity that adjusting sizes may require me to go back a step and resize the full shapes (which I saved in a separate artboard!)

Now I simply need to wait for the proper sizes from the printer and I can then start adding the graphics, text, etc...

I believe there is not need for bleed because, if I wanted to have it, say, all blue, I would just colour the whole artboard, correct?

Copy link to clipboard

Copied

Perfect.

As we've noted before - you can use the extra space to make some business cards or something.

Depends on the finall design - number of colors and extra finish - you can save a bit if you don't need full color and go for spot colors - blue, green and black? Or full CMYK.

Matt foil all over and spot lacquer - over green parts only - should look great.

Copy link to clipboard

Copied

you can save a bit if you don't need full color and go for spot colors - blue, green and black? Or full CMYK.

It's been a long time since I found even 2-color to be cheaper than process. I haven't run a spot color job in... many years. I'd reserve spot color for high-end work that absolutely must match a corporate color chip, or very large runs where the scale might be cheaper than process.

Just as with logic technology, it's become far easier and cheaper to use big-scale processes in simple ways rather than build up from simple elements. 🙂

Copy link to clipboard

Copied

If there will be ONLY three colors - green from the previous screenshot, black for text and mentioned blue background - I think it will be much easier to get colors "right".

But yes, if it will go on a digital printer - then it doesn't matter so much.

Copy link to clipboard

Copied

It's all about price. Yes, you can run K+2 multicolor... but check with your banker before you price it. 4C will do a very good job with very close color matching for... 1/10th the price. And this all triples for what I am sure is very small-run printing best done digitally anyway.

But who knows. I once did a business card with 4C+2 custom spots and a foil ornament, back before there were shortcuts for any of this. Micro-directed by the client, a person of no talent and lesser esthetics. Ugliest thing I've ever done. It came out to about $2.50 per card but the client was absolutely thrilled. Ya never know.

Copy link to clipboard

Copied

I believe this will be printed in CMYK, since it will use the same colours I normally use for the non-slipcase printing. I will show you the result as soon as I have it—both digitally, and in printed proof.

With my ordinary editions, I use a white background with a coloured object and black text.

For these folders-like editions, to make them stand out, I am planning to reverse: coloured background with white object and text. Will need to try!

Copy link to clipboard

Copied

Good luck.

For white text - the background will have to be dark, very dark... Unless you can play with a shadow or an outline...

Copy link to clipboard

Copied

I asked the printer how wide should be the spine for this set of score and parts (28 pages main score, plus 8 inserts of 8 pages each, all staple-bound / saddle-stitched). I also asked if there was a formula to determine the ideal width of the spine.

They told me "there is no formula" and 8mm will be fine...

1) if there's no formula, how do they know?

2) isn't 8mm... way too little for something like this?

Please notice that stapled scores, which get open and closed very frequently, tend to stay more open than when they were freshly printed and bound, and thus tend to occupy more space.

Any idea?

Copy link to clipboard

Copied

I worked as prepress for a commercial printer: this is how WE know.

Every paper stock has a caliper thickness in its specifications, so based on that number, times the number of pages, we can determine how thick, say, a 200-page document on a particular paper stock will be (+ covers) even before we order in the stock... from this we can tell our clients how big to design their spines. Without knowing what your paper stock on the scores is, I can't say if 8mm is truly appropriate or not for your total of 92 pages, but for comparison, I just pulled a document off my shelf printed on 80 lb text, and measured 92 pages of that: it comes out to 6mm. Typically, on perfect bound spines, I add 3pt (1 mm-ish) to the caliper, so my spine would have been 7mm on these 92 pages. So 8mm sounds fine.

A good printer will make up a mockup for you out of the proper paper stock so you can dry fit things and adjust accordingly. I suggest you approach it that way.

Copy link to clipboard

Copied

The paper is 100gsm, don't know what that is in 'lb' measurement.

For such small booklets, there would not be a perfect-bound spine, but just staple-bound.

Copy link to clipboard

Copied

We tend to talk lbs in North America (although here in Canada we go both ways depending on the paper manufacturer). 1 lb = 1.48 gsm (grams per square metre), so 100gsm is just under 70lb, which is a typical text stock. That being said, that's the weight of the paper, not the sheet thickness. Uncoated stock or highly textured stock can be considerably thicker than smooth-calendared/coated stocks.

I wouldn't worry so much about the saddle-stitching. A 28-pager doesn't have that much bulk to it, so the spines lay pretty flat (looking at a 32-page newsletter I have a sample of), and they will flatten once they are inserted in your slipcover and the cover wrapped back around them.

Again, you could ask the printer to prepare dummies for you where they actually take the stock and make up a stitched 28-pager and the 8 8-pagers. then you can measure something tangible. Still, I think 8mm is a pretty good guess and would be roomy enough that it won't be too loose/too snug, but also allows someone to slide additional things in along with the scores should they want to.

-

- 1

- 2

Find more inspiration, events, and resources on the new Adobe Community

Explore Now