Copy link to clipboard

Copied

Dear all,

in my sheet music publishing journey I have now come to a point where I need to create a slipcase to house printed orchestral parts or editions made up of multiple elements (score + at least 5 parts). Here's an example of what I am trying to obtain:

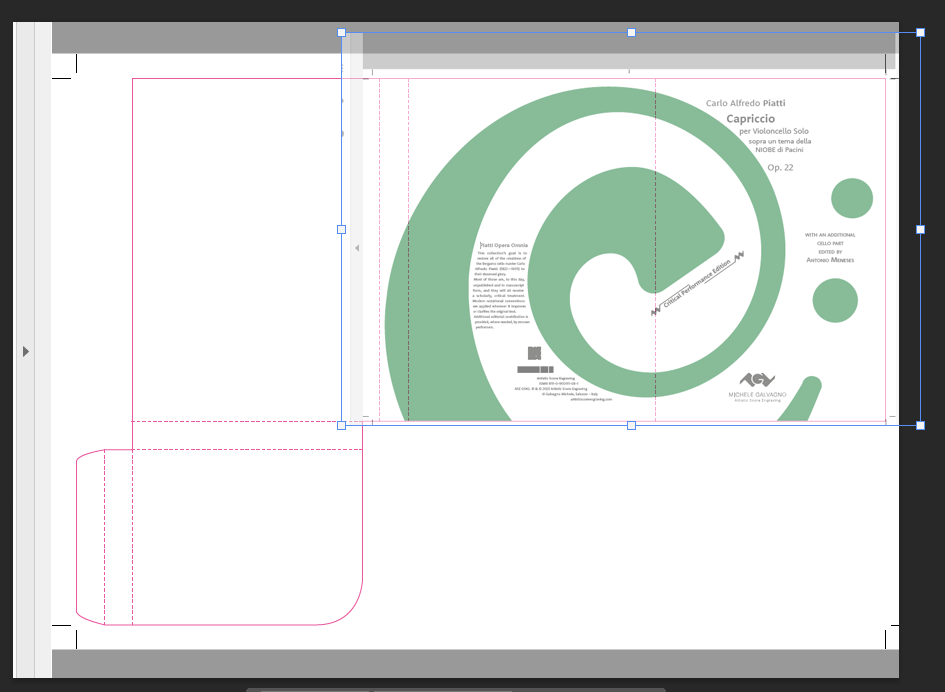

An example of a cover from one of my recent editions is attached below (Piatti-Niobe-op22-Cover_v2.pdf).

The printer sent me a PDF of a model they use for creating a slipcase (also attached below). Looking at that model, though, I am having a hard trying to understand how it is supposed to be folded, since it looks upside down to me, as if the design had to go on the opposite side of the PDF.

So, here are my questions, hoping that someone with experience in this sort of things could help me learn how to do this:

- is this PDF model good and how would I go about creating a design for it? Is it possible in InDesign or should I use Illustrator? I am not too comfortable with Photoshop but could learn of course.

- is there any other model/template available (free or paid) for this kind of objects?

Concerning size: my editions have a page size of 232 x 305mm. How would I then go on calculating the proper dimensions for this slipcase? I am aware of some tools for the depth of the slipcase itself, as if I had to calculate the width of a book spine, but in my experience this is often too small—score and parts are saddle-stiched and after they get opened once, they tend to occupy more space than before.

Thank you so much to everyone who will be able and willing to help me learn this new, fascinating side of my activity.

1 Correct answer

1 Correct answer

"Do you suggest getting started in Illustrator and then moving to InDesign?"

I personally, based on your design I would do the entire project in Illustrator, but you can use both without issue. The dieline is much easier to create in llustrator. Since you already have your design in ID, leave it there. You will have to resize your ID document though as you need to make it as large as necesssary to accommodate all the panels and flaps in the dieline.

"When you say that you prefer to keep the pane

...Copy link to clipboard

Copied

InDesign works well for packaging design. Among other things, you can import layout PDFs, place them on a locked layer, and once you have them precisely scaled, have a much simpler job of laying out each panel in the correct orientation.

You do turn off that layer before exporting.

Copy link to clipboard

Copied

The dieline (template) you were sent can be used either direction. It depends on how this printer likes to diecut the printed sheets. Some like doing it from the front, others the back. (We always do it from the front)

Regardless, what they sent is completely the wrong size for your page sizes anyway, so I think they sent this purely as an example of how a dieline should look; what you have been provided is for a glued pocket (hence the glue flap at bottom right) with a wrap around the front and half a panel further. If you want to see how it folds, print it out smaller on a sheet of paper and cut it out and fold up!

Yes, you could search for a specific dieline for your situation, but my guess is that will be a needle in a haystack search. Most printers have art departments that can create an appropriate dieline for your situation Printers tend to have a stock of standard dies they would use regularly (like a standard folder with pockets), but I doubt they will have one on hand that matches your situation, so you'd be creating a custom one. Coincidentally, I have a similar dieline from an old job...it was for smaller (US letter-sized) inserts than your situation and has smaller spines, and the flaps weren't glued, but it's essentially the same layout. I attach it here in PDF (but can be opened in Illustrator) if you want to use it as a starting point:

Add a few mm top and sides of the front and back panels to give the scores some breathing room (5mm perhaps). Your sample looks pretty tight, so mabe use your Bach sample for guidance there. You willl have to chat to your printer about what size to make your spines based on the caliper of all your inserts, tho.

Place the dieline on a separate layer on top of your InDesign artwork so you can turn it on or off as needed for your final print PDF (I tend to supply separate PDFs for the base art and the dieline, rather than keep it combined in a single PDF).

Notes: use a spot colour for the dieline (set to overprint). My file doesn't use dotted lines for the fold score lines like in their sample, but that's a personal preference as I find it easier to keep the panels and spines as separate sizeable objects; the printer will know what to do!

Copy link to clipboard

Copied

Thank you both for your excellent input!

@James Gifford—NitroPress : what do you suggest the workflow should be? Can one do everything in InDesign? Should every panel be one page or should they be shapes on a page?

Brad @ Roaring Mouse : thank you for the template and for opening my knowledge to this terminology. As a musician / music engraver, I have never followed dedicated studies for this, and I appreciate your patience in explaining things that may sound basic to you.

Indeed, the printer sent just a generic model, not sure they would be willing to create one for my specs and, honestly, it sounds like a fundamental skill to learn. Once you mentioned 'dieline', the web-search returned many more results, but nothing I found looked close to what I need.

Do you suggest getting started in Illustrator and then moving to InDesign? Yes, my sample cover is the same size of the inner pages because—at least in music printing—saddle-stitching works up to a certain number of pages (80, but I'd rather not go up there), after which one switches to perfect binding (softcover).

If I understood correctly, the dieline layer should be the top one, and the artwork, text, and everything else, should be on separate layers below that. I prefer to design this as if I looked at the slipcase un-mounted/un-glued laying down on a table from the outside, not from the inside (btw how would one design things flipped and then print reversed?).

Concerning colour: I have read about the 'overprint' feature in Illustrator but I'm not sure I've grasped the concept fully. Is overprinting allowing for colours to mix on the page instead of the top colour 'obscuring' everything below it? Forgive my rough terminology. Why would that be a better option for my use case?

When you say that you prefer to keep the panels and spines as separate objects, do you mean that you keep them as separate artboards in Illustrator?

Finally, could you suggest some textbooks where to learn about the subjects covered here (printing practices, colour theory / usage). Anything you would feel fundamental if you had to train yourself today!

Thank you so much!

Copy link to clipboard

Copied

I think the answer to this has already been made clear, but the proper way is to do it as one contiguous layout, so that when printed, and then die-cut (and scored to make folding easier), it's one piece that folds up and glues together. Getrting all the panels in the right place and orientation can be bewildering if you don't use a die-cut outline or other template right in the doc.

But all of this other than some graphic elements should be do-able in InDesign.

This really isn't a project for in-house production, unless you're fortunate to have a printer that can handle tabloid-plus (12x18 inch in US sizes) pages. Otherwise, you'd have to go the other route you suggest, make pieces no more than your printer sheet size, cut them out, and glue them together. That can be done, but it's a huge 'art project' and often not very durable. Look at at least short-run production for something like this.

Copy link to clipboard

Copied

What do you mean by "scored to make folding easier"? The usage of the verb "scored" is what puzzles me.

Got it, one contiguous layout. I will draw the sample on paper and then try to reproduce it in either InDesign or Illustrator. Would you guys mind if I posted my progress here for feedback?

Of course I will not print this in-house, maybe a scaled down sample to play bonsai!

The idea is to print between 100 and 200 copies of these, and send them to the distributor.

Copy link to clipboard

Copied

In printing and bindery, a score is a partial cut or a compressed line that makes folding easier.

When something is cut down, it's either a shear cut (straight, as in trimming down to a rectangle) or die cut (cut with a shaped blade). When something on heavy stock needs to be folded, it helps to score it with a dull, even rounded blade so that there's a crease or pinched line that makes the fold easier, straighter and keeps it from breaking (especially those partial-break 'flakes' that look so terrible).

Sorry, didn't occur to me that you have a very different definition for the term!

Copy link to clipboard

Copied

No problem, that's on me!

As a musician, a score is the book where the music for the whole ensemble is written down, compared to "parts" where only the music for a specific section or single musician lives.

Thanks for explaining! I feel such a thirst for knowing more and more about all this! 🙂

Copy link to clipboard

Copied

"Do you suggest getting started in Illustrator and then moving to InDesign?"

I personally, based on your design I would do the entire project in Illustrator, but you can use both without issue. The dieline is much easier to create in llustrator. Since you already have your design in ID, leave it there. You will have to resize your ID document though as you need to make it as large as necesssary to accommodate all the panels and flaps in the dieline.

"When you say that you prefer to keep the panels and spines as separate objects, do you mean that you keep them as separate artboards in Illustrator? "

No. One artboard. If you look at my sample file you will see each rectangle (e.g. for the front cover) is a separate rectangle. Using these building blocks it's easier to snap them together to each other to form the whole dieline. One could then select all those objects and use Pathfinder to Unite them all into one shape (remember, the dieline is basically one big cookie cutter shape) then add back dotted lines for the scores, or use a different colour, like attached:

Copy link to clipboard

Copied

Thank you!

I've actually created the design in Illustrator and then moved it to InDesign so I may very well try all the process in Illustrator—I am less comfortable in it but it would prove a great motivation for improvement!

I will let you know how it goes!

Copy link to clipboard

Copied

Exctly like that.

Back in the days, we were sneaking in some extra business cards on the sides.

When client was ordering extras - local lacquer or matt foil - we used it to accent some texts / logos on those business cards - or just use lacquer / foil instead of the text - so the text / object will only be vesible at an angle + can be felt without embossing.

Copy link to clipboard

Copied

Back in the days, we were sneaking in some extra business cards on the sides.

Humph! We never did no such thing to squeeze in small or personal jobs on big layouts. The very idea. 😮

Copy link to clipboard

Copied

We never did that either!! (gigantic halo) 😉

Copy link to clipboard

Copied

Why not??

Client is paying for the design and finall piece of paper - why the rest - usable offcuts - should go to waste??

Copy link to clipboard

Copied

Humor alert, Roberto. Of course we did lots of marginal jobs on things. I think the statute of limitations has expired on most of mine.

Copy link to clipboard

Copied

Right, misinterpreted the "face expression".

Copy link to clipboard

Copied

PRint out the dieline on as large a sheet of paper you can. If all you have is 8.5˝ x 11˝ then use that. It’s okay to reduce it to fit. Cut it out with ruler and knife, score along dotted lines, then glue or tape it together. This will give you a better idea of how the parts fit together, which panel is upside down (the small one hanging down) and how the panels will look in context with one another.

Copy link to clipboard

Copied

Dotted lines represent folds.

Copy link to clipboard

Copied

Just a quick mockup done in Photoshop from screenshots from Acrobat:

Assuming that what you have on your die-cut PDF is the look "for inside" - you need to flip it then overlay your design.

Copy link to clipboard

Copied

If you want to save some money - maybe they have a version that doesn't need gluing but have flaps that can be locked together.

https://www.glideprint.com.au/presentation-folder-templates

and you can download them from this webste.

But looking at the size of the flaps - you probably will need it to be glued together...

Or, you can just glue it yourself - if it's not a big volume...

Copy link to clipboard

Copied

Hi all,

this morning I have created a very rough paper mock-up, cut it out, folded and checked that it worked as I wanted it to.

I then created a graphical mockup on Apple Freeform app, on iPadOS, and got the attached result.

Could you please tell me if this makes sense? It should give the result shown in my Bach example above.

If it does, I should start drawing this in either Ai or Id. Could you please advise on layer management?

@James Gifford—NitroPress explained what the 'score' is, but it's not clear to me what makes it different from the 'dieline', since Brad @ Roaring Mouse showed two different colours for them.

Is it good to create shapes (rectangle, trapezoid, etc...) and then simply make them "collide"? Then yes, Pathfinder if needed.

I have seen a few examples where the external stroke is solid and the internal (folding) ones are dashed.

What do you suggest?

Thank you!

Copy link to clipboard

Copied

The 'dieline' is the custom cut line, created by assembling straight and curved blades on a plate to form a "die" that will cut out the custom shape when it's pressed into the paper stock (with several hundred pounds of force).

A 'score' is created by a dull or rounded edge, so that instead of cutting through, it compresses the stock so that it will fold cleanly and well along that line. They are sometimes part of a cutting die, and sometimes done as a separate operation. (When you have flat goods that will be folded, such as a greeting card, scoring is done by running the printed flat through a machine with a scoring wheel that makes that one straight "pinch.")

(Again, sorry for any confusion on the latter term. I come from a family of musicians who both use and write scores, and even score movies... so I should have known to explain it a bit better! 🙂 )

Copy link to clipboard

Copied

No problem, James! Thank you for your patience!

Maybe oversimplifying:

- dieline = the big external cut that will create the single piece of cardboard that will one day be a box

- score = folding paths

Am I getting closer?

Copy link to clipboard

Copied

@Inélsòre wrote:

- dieline = the big external cut that will create the single piece of cardboard that will one day be a box

- score = folding paths

Exactly.

Copy link to clipboard

Copied

Almost perfect - all those objects should be close together to create one shape.

And like you've summarised in another reply - outside is the diecut line - and where objects touch each other - are score / folding lines.

-

- 1

- 2

Find more inspiration, events, and resources on the new Adobe Community

Explore Now